Tariffs and automation are at the forefront of current economic discussions, particularly with the implications of the Trump tariffs being felt across various industries. As manufacturers grapple with higher production costs, the push to automate labor-intensive jobs is gaining momentum. Despite President Trump’s intention to revitalize manufacturing jobs in the U.S., many economists warn that the very tariffs designed to bring jobs back may ironically lead to increased automation in industries like automotive manufacturing. The rapid advancements in AI and robotics have made it economically viable for companies to replace human labor with machines, particularly in a climate where labor costs are escalating. Thus, while tariffs are meant to secure American jobs, their unintended consequence could be a boost in automation, leading to a reevaluation of the future job landscape.

The recent discourse surrounding trade levies and technological innovation has ignited a debate on their potential consequences for the labor market. As the administration’s trade policies—especially those resembling the Trump tariffs—come into effect, many manufacturers find themselves at a crossroads. They must decide whether to invest in human labor or to pivot towards automation in manufacturing processes to mitigate higher operational costs. The increasing integration of smart technologies and robotic systems into production lines brings with it both opportunities and challenges. As the landscape of manufacturing evolves, a clearer understanding of how tariffs influence the adoption of automation is essential for navigating the complexities of modern industry.

Understanding Trump Tariffs and Their Economic Implications

President Trump’s tariffs were touted as a means to rejuvenate the American manufacturing sector, particularly in the automobile industry. The initial intention behind these tariffs was to encourage companies to bring manufacturing jobs back to the United States, thus helping to revitalize areas like Michigan, which have faced significant job losses. However, the economic reality presents a more complex scenario where the introduction of tariffs generates debates about whether these policies truly benefit American workers or merely set the stage for increased automation.

Economists have raised concerns that the implemented tariffs might lead to unintended consequences, particularly with respect to automation. The argument hinges on the simple fact that higher labor costs in the U.S. incentivize companies to automate labor-intensive processes to maintain profitability. As companies face elevated operational expenses due to tariffs, they may increasingly look towards technology and robotic solutions to mitigate costs. The net effect could be a reduction in the manufacturing jobs that the tariffs were intended to protect.

The Impact of Automation in Manufacturing

Automation in manufacturing has been a double-edged sword throughout its evolution, particularly as it relates to job security in the industry. While automation can streamline processes and increase productivity, there is a prevalent fear that widespread implementation may displace workers. The relationship between tariffs and automation is especially pertinent; as tariffs raise costs, manufacturers may find it more viable to invest in robots and AI solutions rather than human labor, especially in production scenarios that demand flexibility and efficiency.

Furthermore, advancements in robotics and artificial intelligence have made automation more accessible and appealing to mid-sized manufacturers. Previously, the high costs and complexity of deploying such technologies were prohibitive for smaller firms. However, as the technology matures and becomes more cost-effective, it may lead to an increase in automation within sectors historically reliant on a human workforce. Consequently, while tariffs aim to protect jobs, they may inadvertently accelerate the shift towards automation, raising ethical concerns about the future of work in America.

AI and Jobs: The Future of Work Post-Tariffs

The intersection of AI and job creation is a contentious topic in the current economic landscape, especially in light of proposed tariffs and their anticipated implications. Many experts posit that while AI has the potential to enhance productivity and create new job categories, it simultaneously poses significant risks to existing employment structures. The fear that automation will replace jobs—particularly in manufacturing—remains a dominant concern among workers and economists alike.

As President Trump’s administration pushes for increased tariffs with hopes of strengthening domestic manufacturing, experts warn that the real outcome may skew towards greater reliance on AI and automation technologies. While there may be a short-term focus on bringing jobs back to the U.S., the long-term perspective suggests a shift where companies favor investing in AI-driven solutions over human labor forces. This dilemma places policymakers in a precarious position, balancing the need to protect American jobs against the irreversible wave of technological progress.

The Role of Tariffs in Shaping Supply Chains

Tariffs significantly influence supply chain dynamics, particularly in the manufacturing sector. When President Trump announced the tariffs, it raised the specter of increased production costs for businesses that rely on imported materials or components. In the quest to maintain profit margins, some companies may be forced to reevaluate their supply chain strategies, which can lead to offshoring or onshoring in a bid to remain competitive amidst rising costs.

However, the immediate repercussions of tariffs are often a disruption in established supply chains, which can create inefficiencies and increase prices for consumers. As companies grapple with these challenges, the inclination towards automation may provide a solution that mitigates some of the adverse impacts of tariffs. In this context, automation may emerge as a key strategy for companies aiming to adapt to a fluctuating economic landscape shaped by tariff policies.

Evaluating the Long-term Effects of Tariffs on Employment

The long-term effects of tariffs on employment remain a contentious and unclear issue. While the intention behind the tariffs is ostensibly to foster job creation within the United States, historical evidence paints a more complex picture. Previous rounds of tariffs, particularly those imposed in 2018, did not result in a significant increase in employment within affected sectors, and many argue the current tariffs may harbinger similar outcomes, especially if they drive companies towards automation instead of job creation.

Economists advise caution, noting that while short-term job loss may occur in sectors affected by tariffs, the shift towards automation could yield more profound, long-lasting changes in the job market. As firms invest in AI and robotics to streamline their processes, the labor landscape could shift dramatically, with many workers displaced by machines. As such, policymakers must consider mechanisms to support workers who may find themselves displaced in an increasingly automated world.

The Relationship Between Tariffs and Technological Advancements

The interplay between tariffs and technological advancements is vital when assessing the future of American manufacturing. President Trump’s tariffs were introduced alongside an era of rapid technological innovation, particularly in automation and artificial intelligence. These advancements pose new challenges and opportunities for the manufacturing sector, where firms are increasingly tempted to integrate automated solutions to offset the impacts of rising operational costs driven by tariffs.

Despite the potential for tariffs to encourage a return to local manufacturing, the burgeoning landscape of AI and robotics may overshadow this goal. With these technologies making strides in adaptability and cost-efficiency, the very tariffs designed to protect jobs could accelerate the shift to automation, reshaping the manufacturing workforce. The challenge lies in fostering an environment where technological progress enhances rather than undermines employment in the sector.

Tariffs and the Economic Incentives for Automation

The presence of tariffs creates a unique set of economic incentives that impact the decision-making processes of businesses. As operational costs increase due to tariffs, manufacturers may find that automation offers a more cost-effective alternative to human labor. This shift could make sense for companies tasked with maintaining profitability in an environment marked by higher production costs, leading them to invest in AI and robotics rather than hiring back workers.

While the immediate goal of tariffs appears to be job preservation, the unintended consequence may well be a fast-tracked transition towards automation in industries previously reliant on human capital. Economists fear that as firms look towards the latest technologies, they risk perpetuating a cycle where tariffs ironically lead to less job security for American workers. Understanding this dynamic is crucial as lawmakers formulate policy aimed at sustaining employment in an evolving economic landscape.

Impacts of Tariffs on Global Trade Dynamics

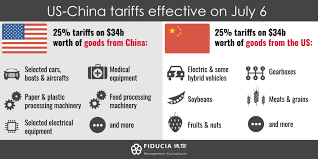

Tariffs inevitably alter the balance of global trade, affecting not only domestic manufacturing but also international relationships. The introduction of tariffs by the Trump administration serves as a catalyst for shifts in trade dynamics, compelling companies to reassess their operational footprints globally. This can lead to trade disputes, retaliatory measures from trading partners, and an overall increase in friction in global commerce.

As tariffs influence where production takes place, companies may turn to automation as a viable solution to circumvent some of the negative impacts of global trade tensions. With pressures mounting to remain competitive without incurring the high costs associated with tariffs, automation could serve as a lifeline for manufacturers. Over time, however, this may result in a less interconnected global economy, with companies choosing to localize their supply chains at the expense of broader international collaboration.

The Future of Work in the Age of AI and Tariffs

The future of work in an age shaped by AI and tariffs presents unique challenges and considerations for workers and policymakers alike. As automation technologies advance, the potential for job displacement grows. Industries that once promised stable employment could find themselves increasingly dependent on AI and robotics, leaving many workers at risk of losing their roles in favor of machines that can perform tasks at lower costs.

Moreover, the welcoming of AI into the workforce necessitates a reevaluation of training and education systems to prepare workers for a future where adaptability is key. Policymakers must prioritize initiatives that support workforce retraining and upskilling, ensuring that the labor force can transition smoothly into roles that are less susceptible to automation. The ongoing discussion surrounding tariffs must incorporate these labor considerations, balancing economic strategy with the interests of American workers.

Frequently Asked Questions

What impact do Trump’s tariffs have on automation in manufacturing?

Trump’s tariffs may inadvertently accelerate automation in manufacturing. While the intention behind these tariffs is to increase U.S. manufacturing jobs, higher production costs might drive companies to invest in automation and AI technologies, opting for robots over human labor. Economists warn that the economic incentive for companies to automate could become stronger as they face increased costs from tariffs.

How do tariffs influence the future of manufacturing jobs in relation to AI and jobs?

Tariffs can significantly influence the future of manufacturing jobs by encouraging companies to adopt automation technologies. Although the tariffs are intended to revive U.S. manufacturing jobs, the high operating costs could push firms to invest in AI and automate processes instead, potentially leading to fewer jobs for human workers in the long run.

Can tariffs lead to job growth in the context of automation in manufacturing?

While tariffs are designed to promote job growth in manufacturing, experts suggest that they may not result in meaningful job creation. Instead, as companies face higher costs, they might choose to automate labor through advanced technologies like AI, thus offsetting the potential benefits of tariffs on job growth.

What role does AI play in the automation of manufacturing jobs following increased tariffs?

AI plays a crucial role in the automation of manufacturing jobs, especially when tariffs increase production costs. Companies are likely to employ advanced AI-driven solutions to maintain competitiveness, which could result in a shift away from traditional manufacturing labor and towards fully automated systems.

How have past tariffs influenced automation trends in the manufacturing sector?

The previous tariffs imposed by Trump in 2018 did not show a significant increase in automation within the manufacturing sector. However, with advancements in AI and robotics since then, the current tariffs might prompt a different outcome, potentially accelerating the trend towards automation to manage elevated production costs.

Will increasing tariffs provide a competitive advantage for automation technologies in manufacturing?

Yes, increasing tariffs may provide a competitive advantage for automation technologies in manufacturing. As companies face higher labor costs, they will be incentivized to invest in AI and robotic systems to enhance productivity and reduce reliance on human labor, potentially reshaping the employment landscape.

What are the potential downsides of automation encouraged by tariffs in manufacturing?

The potential downsides of automation spurred by tariffs include job displacement for workers, reduced manual employment opportunities, and increased efficiency leading to supply chain disruptions. As companies automate, the immediate benefits may be outweighed by challenges such as higher production costs and the loss of jobs that once supported local economies.

How might automation and tariffs interact to reshape the manufacturing industry?

Automation and tariffs are likely to interact in a way that reshapes the manufacturing industry by pushing companies towards investing in robotic technologies to counterbalance higher costs. This shift could lead to a decrease in traditional manufacturing jobs, with a growing reliance on AI and automation solutions to maintain profitability.

| Aspect | Details |

|---|---|

| Tariffs Implementation | President Trump announced tariffs to aid job creation in Michigan’s car factories. |

| Economic Incentives | Higher production costs in the U.S. could lead companies to automate rather than hire more workers. |

| Role of Automation | Economists suggest that tariffs combined with automation advancements may shift manufacturing jobs to robots. |

| Historical Context | Previous tariffs did not lead to significant automation; experts expect this could change due to advancements in AI. |

| Short-Term vs Long-Term Effects | In the short term, companies may delay automation investments, but longer-term, AI could dominate labor. |

| Impacts on Productivity | Automation may disrupt supply chains and heighten import expenses, affecting overall efficiency. |

Summary

Tariffs and automation are poised to reshape the manufacturing landscape in the United States significantly. While President Trump’s tariffs aim to boost domestic job creation, economists warn that they might push companies toward greater automation instead. As the cost-benefit analysis shifts—especially with advancements in artificial intelligence—the relationship between tariffs and labor dynamics could lead to a more automated workforce in the long run. Understanding this complex interplay is crucial for anticipating the future of jobs and production efficiency.